The Olson Advantage

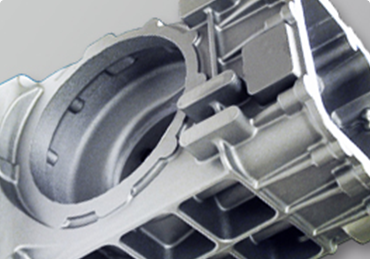

Castings produced by Olson Aluminum will exhibit machining

characteristics equal to, and in many cases, better than bar stock or billet aluminum.Our process begins with chemical property requirements on all incoming alloy. Magnesium levels are controlled to attain a consistent

Brinell Hardness reating (BHN). We complete the process by removing harmful hydrogen gases, oxides and dross prior to pouring. This process, along with our in-house heat treating capabilities, assure superior T6 and BHN results.

Our commitment to these critical process controls assures a high degree of grain refinement and consistency that is necessary to achieve desired characteristics, such as:

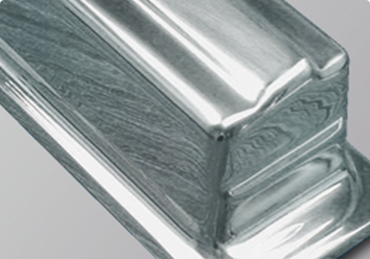

- Superior micro surface finishes

- mproved dimensional control

- Consistent Brinell Hardness values

- Extended tool life

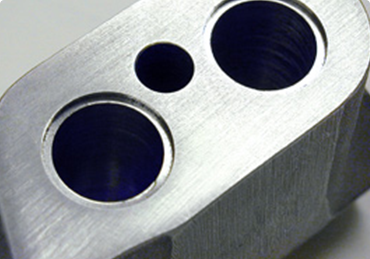

- Reduction of machining burrs and associated costs of removal

- Significant reduction of aluminum oxides (hard spots)

- Elimination of scrap due to porosity and shrinkage

- Improved machine cycle times

- Ability to utilize diamond tooling on sand castings

Ask any of our machining customers “…it is the quality of what you find below the surface of our castings that distinguishes Olson Aluminum from the typical sand cast foundry.“