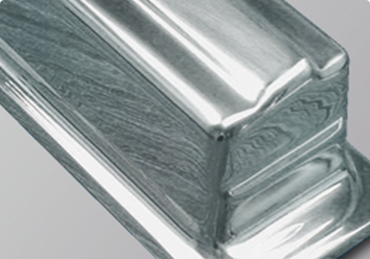

Prototype Castings

Prototype casting programs set the stage for the successful design and introduction of many cast products. It is an expedient and economical approach to developing and testing the fit, form and function of your product design.

Prototype has many advantages, including:

- Improved production lead times

- Proves out both design and manufacturing processes

- Minimizes cost and overall risks in new designs

- Offers an economical forum for product improvements

- Presents opportunities for early cost reductions

- Limits the costs of engineering changes

- Allows for incremental steps in development

- Enhances sales and marketing of “new concepts”

- Accelerates the “time to market”

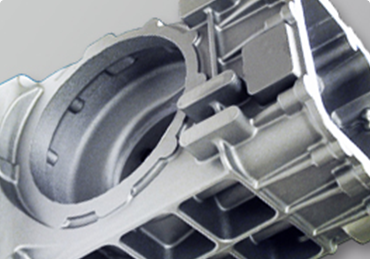

Olson Aluminum Castings has partnered with world class pattern shops whose strengths are found in meeting short lead times and producing

exceptional and highly complex patterns to meet the unique requirements of today’s time challenging programs.

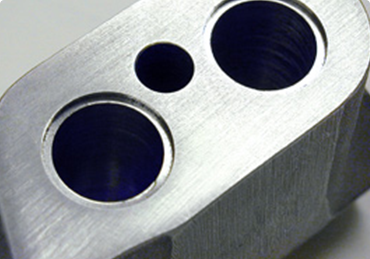

There is a substantial number of excellent and cost-efficient options available to customers when considering prototype tooling. Our staff will help you evaluate a number of options.

Large project or small, prototyping is a value very much worth your time to consider. Allow Olson Aluminum Castings’ design and engineering team an opportunity to get your program off to a successful start.